How does a gasification boiler work?

"burn the Smoke"

The principal of burning wood smoke in a separate combustion location from the wood itself has been around at least since WWII, when much of northern Europe had limited fuel availability and was forced to run vehicles on wood gasifiers, literally burning wood smoke in conventional internal combustion engines.

Since the 1980's this has been applied to wood-fired heating appliances, and in the last decade, has been adapted into outdoor installed wood boilers (hydronic wood heating appliances) as they are typically not pressurized for safety reasons.

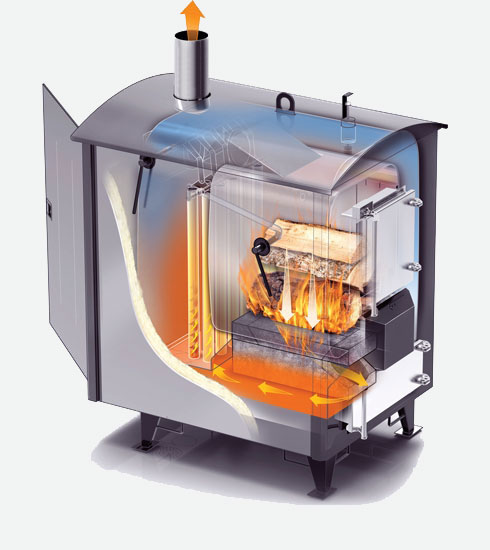

In a Heatmaster G series boiler the upper chamber is loaded with wood (20% moisture content is best in the smallest stove, up to 30% is fine for continuous use in the 200 and 400 series) which is heated by the coal bed at the bottom of the upper burn chamber.

The coal bed causes the wood above it to off-gas (smolder) and the draft fan at the chimney draws the smoke down through the coal bed and through the "throat" where additional fresh air is mixed with it, resulting in a "blowtorch burn" in the bottom chamber.

That secondary "blowtorch" burn can be up to 2,000 degrees F, resulting in complete combustion with nothing left but some fly ash and the mineral content of the wood. 1-2% ash is pretty typical, meaning that for every 100 cubic feet of wood burned, only 1 cubic foot of ash results.

Wet wood will reduce the temperatures in the upper chamber (the energy needed to boil the water and dry out the wood before it can burn comes from that upper chamber) and reduces the output of the boiler. It will also increase the emissions of the boiler because the second chamber never gets as hot as it would otherwise, leaving more unburned materials.

This additional unburned material can collect in the flue tubes and chimney, and results in more cleaning of the boiler than if dry wood is used.